Technology & Quality

Technology & Quality

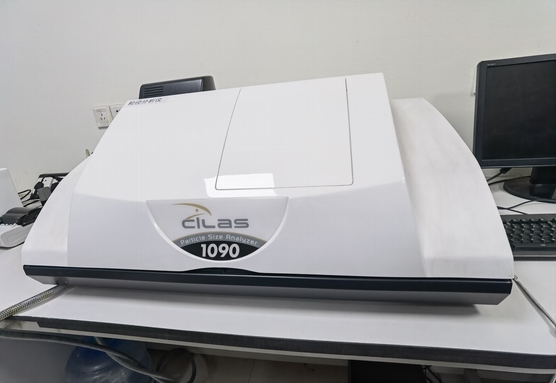

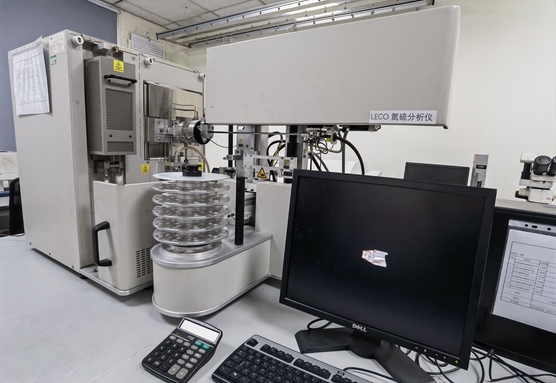

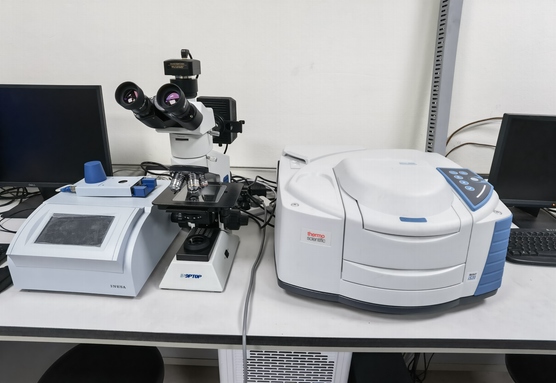

In line with the Kafrit Group, Suzhou Constab Engineering Plastics Co., Ltd. emphasizes that quality is the life of the enterprise and has certificate of quality system ISO9001:2015, the occupational health & safety system ISO45001:2018 and environmental management system ISO14001:2015 which are tailored for the production of compounds and masterbatches. With foreign advanced testing instruments and equipment, the senior quality management team ensures stability and accuracy of product quality from both hardware and software.

Rigorous quality control system runs through every link of raw material procurement, production and product delivery, and every lot of products sold comply with CONSTAB quality control standards.

(1) Perform strict incoming inspection of raw materials and adopt CONSTAB global unified quality system to control material selection, quality and stability.

(2) The masterbatches produced online are routinely tested (MFR, moisture, appearance, color, density, bulk density etc.); strict control of additive content in each lot; other special tests (such as pressure filtration tests against the dispersion of the adhesive masterbatches etc.) effectively ensure the stable performance of each lot.

(3) The finished goods must be strictly reinspected before leaving the factory to ensure that they meet the formula design requirements and performance indicators.

(4) The laboratory information management software is combined with the intelligent early warning system of the production line to realize the information and process management of all process activities in production, the synchronization of test data, and real-time monitoring and alarm to ensure the quality and stability of each lot of products.

(5) The laboratory can complete a full range of tests from additives, finished goods and downstream final applications, providing customers with satisfied solutions.

(6) Continuous improvement of product quality, work efficiency, and system quality has promoted the development of enterprises.